Plastic littering is an increasingly big problem all over the world and single-use products are one of the problems in the fight for a circular economy. The Swedish company PulPac has created a climate-friendly and resource-efficient option to traditional single-use fossil packaging.

The R&D company PulPac, founded in Gothenburg in 2018, has invented the first industrial method that can convert cellulose fibres into packaging that is price-competitive enough to replace single-use plastics at scale.

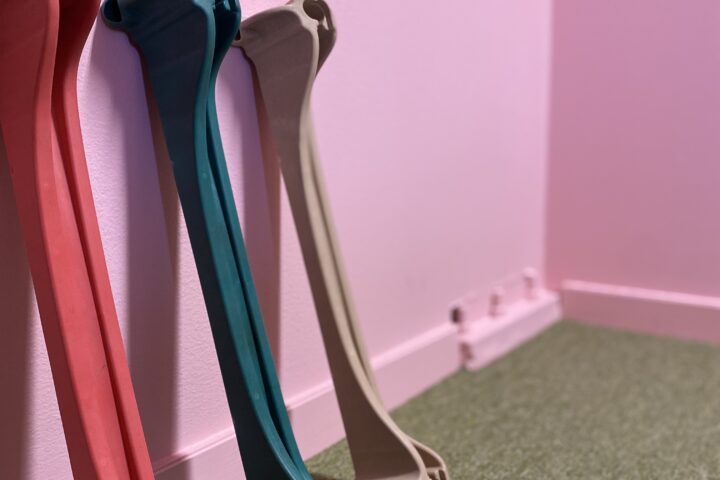

By using dry moulded fibre as the manufacturing technology, renewable pulp and cellulose resources are used to produce fibre-based packaging and single-use products that are climate-friendly and resource-efficient. According to the company, the use of dry moulded fibre gives an 80–90 per cent lower carbon footprint to a cost that is the same or even lower than plastic. It also enables high-speed manufacturing, allowing it to replace some single-use products presently made of plastics.

Since PulPac’s technology is presented in a dry process, it also saves water and does not generate any wastewater. It is possible to utilise all types of cellulose fibres in the production process, such as virgin, residue, or recycled fibres.

Climate-friendly packaging technology

PulPac’s technology is offered on a licensing basis to manufacturers that set up their production capacity. The technology platform is versatile and can manufacture most single-use applications presently made of plastics. Currently, the most common products are trays, bowls, soda lids or spoons.

PulPac’s vision is to be a world leader in innovative packaging that is both sustainable and commercially successful. And they have come a long way. This year, PulPac revealed its the world’s first standardised, automatic production line, ready for food-grade production. Raw paper pulp is fed through a mill to break it up into fibres, which are then formed into a web that is fed into a standard plate press. The press is equipped with unique tooling that compacts the fibres into a mould.

Replacing one million tonnes of plastic

A selection of global brands and manufacturing leaders are presently implementing the technology and the first end-user products will reach the market this year. PulPac aims to have replaced impressively one million tonnes of plastic with dry moulded fibre by 2025.

PulPac recently received a grant from the US patent office for its dry moulded fibre and the same patent application was recently approved in Japan, with other patents granted in China and Europe earlier this year.

The company was also one of the finalists in the sustainability awards 2021 in the resource efficiency category. The winners will be announced later this year.

Get in touch with PulPac here.