With new digital technology, such as smart robots, connected sensors, easily navigated drones and cloud services, comes the potential to develop smart and sustainable cities. The waste sector, which so far has had a relatively slow start on its digital journey, now has the potential to leapfrog into the digital era. Promising new technology, combined with new services sprung from data-driven insights, will most likely affect the role of waste management in the smart city, but how can you meet the opportunities that the digital era brings?

The waste sector and its waste facilities have an important role in the digital ecosystems that are being developed to reduce society’s environmental impact and create new sustainable solutions. To accelerate the journey to increased digital maturity, IVL, together with the Swedish Waste Management Association, have conducted two projects with the aim to support, inspire and guide the Swedish waste sector on its digital journey.

When IVL asked representatives from the waste sector what they need to engine their digital transformation, we found that sharing of experience from the own sector is most appreciated. Therefore, we have been looking for examples of successful digitization at waste management companies and waste facilities both in Sweden and other countries. The fact is that we have found quite a lot.

Among the best practice examples found were the family-owned waste and material management company Carl F. At Carl Fs’ facility in the south of Sweden, a new type of employee: The robot Carl-Robot, developed by Zen Robotics, was introduced a few years ago. Carl-Robot became a part of Carl Fs’ business solutions as the company started to look for more efficient solutions for waste management. Today, in full operation 18 hours per day and up to 4000 picks per hour, Carl-Robot has contributed to reduce the need for fuel from 40% to 15%. It has also made it possible to optimize the plant to achieve an industrialized sorting and add additional materials to the cycle.

Another example came from a waste facility owned by VafabMiljö, a municipal association that handles waste from a region with about 330 000 people and more than 10 000 businesses. In 2016, the company decided to invest in drones to support estimations, validations, and planning of the facility. Since then, they have found several application areas for drone technology. E.g., to measure the size of the landfill and volume with meter precision and create 3D models over the landfill, which helps to quickly produce updated maps throughout the plant and get precise information about current volumes of material stocks. This has also helped to optimize transports and logistics to and from the facility with reduced emissions of CO2 as a result.

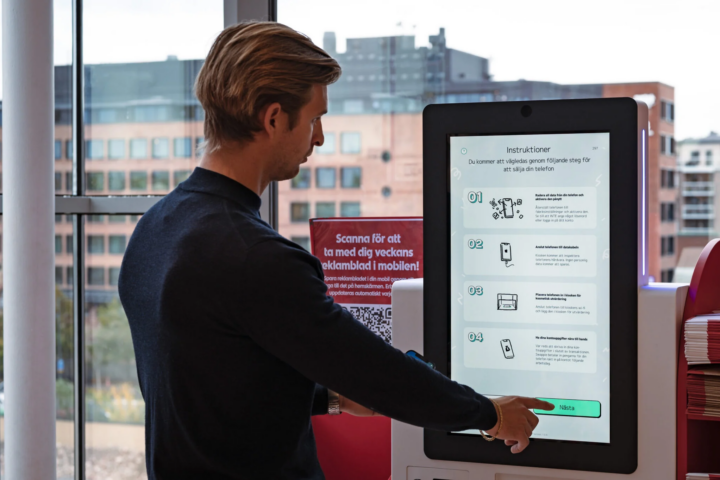

Another company that has contributed with best practices from digital solutions that include several types of waste facilities is BIR AS, Norway’s second-largest waste management company, responsible for waste handling from approximately 356.000 inhabitants in the Bergen area.

We hope that BIRs’ way of broad front digitalization, including both business systems and new digital solutions for customer recognition and self-service at recycling centres, will inspire others to introduce digital solutions and become data- and insight-driven.

The results from the two projects, including the examples mentioned above, were published in six thematic white papers that are free to download from IVLs’ website (in Swedish) here.

The themes covered are:

- New opportunities that the digital era bring and what is needed to meet these opportunities.

- More efficient logistics with the help of sensors and cloud services

- How to increase customer focus and meet customer needs

- Digital support for waste prevention and increased recycling

- Systems that can optimize business and create new/added values

- Smart technology (sensors, robot, drones etc.) that paves the way for effective solutions

This article was written by Eva Stattin, Senior Expert and Project Manager – Sustainable Digitalization and Innovation at IVL Swedish Environmental Research Institute.

Contact: Eva Stattin, eva.stattin@ivl.se