Why are waste bins equipped with e-smart sensor devices beneficial for the environment? And how do you order a carton of milk on your phone? Swedish cleantech companies have the answers to these and other questions. Their technical solutions may be crucial when it comes to maximizing the sorting necessary to transform waste flows into resources under a circular economy.

Everyone knows this: many raw materials are finite resources, and we will need to reuse them many times over if we are to achieve the goals of the Paris Agreement. Despite this, we still incinerate our waste, or even worse, bury it in landfills. This is not only a huge waste of materials but also risks emitting both carbon dioxide and toxins into the environment and atmosphere.

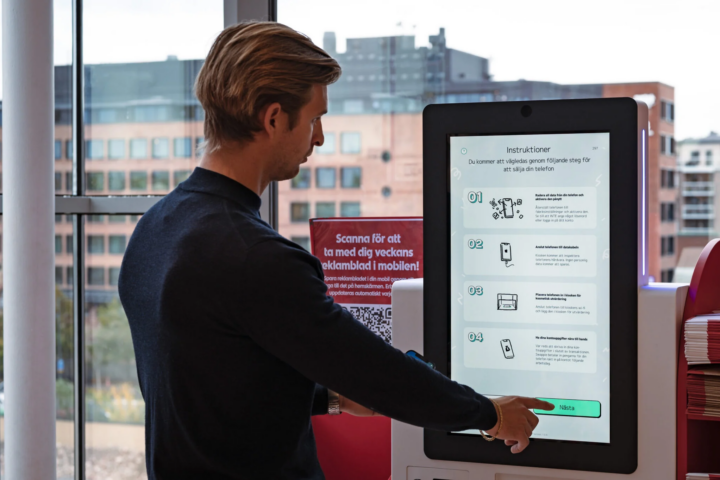

But today, many simple, technical solutions are available to facilitate sorting, which is a prerequisite for recycling. An example of this is an app developed by the Swedish technology company Bower that makes it possible to redeem the deposit on many different types of packaging without the need for further investments in infrastructure.

– All that is required is a package with a barcode, a phone and our app, explains Suwar Mert, founder and CEO of Bower.

– No special machines and or extra logistics are needed.

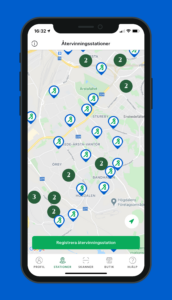

Deposit stations in the Bower app

It works like this: you take the used packaging to a recycling or environmental station, and the app uses the phone’s navigation system to verify that you are located at an approved recycling centre. You then scan the barcode on the packaging and points are added to your account. Points that can then, for example, be converted into money.

– If the packaging comes from one of our partners, say Unilever, you are given two points, if it comes from another supplier, you are given one point. The important thing here is that we accord waste products a value so that the consumer is incentivized to return rather than discard them.

But the manufacturer is also granted value, in the form of more data on how consumers use their products.

– The app can also be used to ask consumers questions, allowing the manufacturer to gain new insights into consumer habits. In addition, our solution can be installed regardless of the country because it utilizes the existing infrastructure. This makes it feasible to introduce a deposit scheme at short notice, thereby increasing sorting and recycling, in many more places and for a lot more items than previously.

In Sweden, Bowers’ country of origin, recycling stations for glass, cardboard, plastic packaging etc., are distributed throughout all municipalities. This means that it is convenient and easy for people to return packaging for recycling. However, if residents are to be comfortable using these recycling stations it is necessary that they be kept clean and tidy. Unfortunately, this is not always the case and visitors are met with dirt and overflowing containers. To remedy this, Bintel, another Swedish environmental technology company, has begun equipping waste bins with sensors.

– The data the sensors generate makes it possible to address three separate problems, says Bintel CEO, Michael Wictor.

Michael Wictor, CEO at Bintel

– Firstly, you can streamline logistics. Instead of emptying waste containers on a fixed schedule, you can do this as needed, which makes it possible to optimize transportation. Secondly, you avoid overfilled waste containers and foul-smelling environmental stations, which makes using the facility far more pleasant, and encourages people to do the right thing, which steps up the recycling rate. Thirdly, you can easily track the fill levels in the waste containers and see how these fluctuate if, for example, you are running a targeted information campaign.

And although all these three aspects are important, there is no doubt which of them Michael Wictor thinks has the most potential.

– We must of course reduce our consumption, but we must also stop incinerating waste streams and emitting vast quantities of carbon dioxide unnecessarily. When we equip the containers with sensors and use the data this gives us to trim the way we deal with the waste we are able to ramp up sorting, which leads to more waste being collected rather than incinerated. In addition, we remove plastics from residual waste and that is what makes the big difference in carbon dioxide emissions.

So far, Bintel is located in Scandinavia, Finland, Germany, Belgium, Italy and Croatia and has approximately 11,000 sensors deployed.

– But we have only just started because we are on a global mission. We will build the company as big as we can because the bigger we get, the more we can utilize our technology to make the world a better place. The big challenge now is to develop our AI solution which will allow us to automate data processing – when we succeed in doing that, we will be able to scale this up for real.

Text: Karin Aase