The increasing amount of waste is a worldwide problem. As citizens are becoming more aware, the demand for recycled materials for sustainable design and circular production is increasing. The Swedish company Sculpur is making use of waste by turning it into other products, such as furniture. The idea is to keep the materials in a loop as long as possible by using innovative design and technology.

How it works

Sculptur, founded in 2019, is a Swedish company that creates design furniture out of waste such as fishing nets, coffee grounds and wood fibre. They do this with 3D technology where robots are used to print the furniture.

The idea behind Sculptur started already in 2016, when ABB and RISE (Research Institutes of Sweden) together came up with the idea of additive manufacturing (AM) production using robots. As a result, Sculptur was created.

Sculptur uses materials from coffee, polypropene, wood fibres, fishing nets and recycled ABS plastic. Thanks to a global network of printers, where digital files are sent among each other, the products can be produced locally, close to the customer. This reduces transports and decreases the environmental impact.

The technology behind

The material used is in the form of pellets or shredded parts. This goes into the plastic extruder, where it is melted. Beads of this molten plastic are then placed on a heated bed, layer by layer, until the finished product is built.

The pathway of the robot is controlled by Adaxis software. This is the slicer Sculptur uses for its large-scale printing to slice the product into the different layers comprising the ready product.

The system needed to print a product includes a robot, plastic extruder with heating and feeding system, print bed and drying systems. The equipment is developed together with Spectram Technologies, which delivers the full system for printing.

Turning old car parts into seats

Sculptur is involved in several projects to make waste into products. In a new project with car manufacturers Volvo Cars and Volkswagen Group, Sculptur will make use of parts from old cars and make them into new products. By adding glass fibre to the recycled plastic, a strong material is created that is used to make design furniture. The furniture will also be equipped with a QR code where the customer will be able to get information about where the recycled plastic comes from.

From coffee waste to coffee stations

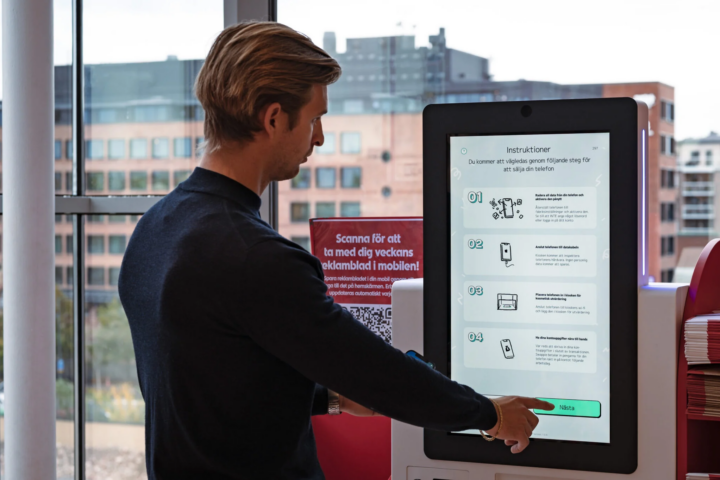

Together with Swedish coffee group Löfbergs, Sculptur transformed coffee production waste into brand new coffee stations. The collaboration is part of the Circular Coffee Community and the pursuit of the group’s ambition of zero coffee waste by 2030. The World’s first 3D printed waste-based coffee station is already in operation and more are underway.

Shifting production in a crisis

During the Corona crisis, the demand for protective equipment increased. By printing a conveyer belt, Sculptur printed almost 1000 pieces a day. The project showed the possibilities with the technology, as well as the quick transition from idea to production.

Interesting in learning more? Contact Sculptur here.