SWESTEP presents a ground breaking, nature mimicking Catalytic Conversion Technology, turning organic and plastic wastes and residues into CO2 neutral energy, fuels and oil substitutions.

MISSION – Replace the world’s fossil dependency by making Swestep’s environmentally and economic viable recycling technology available globally.

VISION – Become one of the solutions to the global waste challenges and a fossil free economy. (Biomass to Liquid and Energy – Waste to Energy and Liquid)

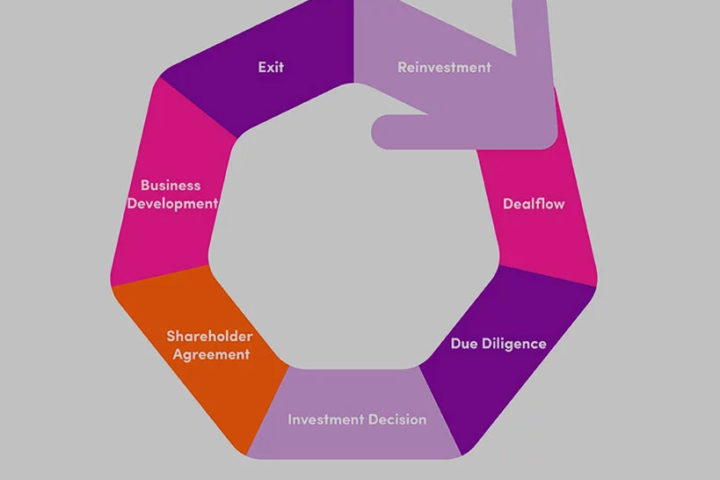

BUSINESS – Develop, sell and market SWESTEP Plants for both small and large scale installations regardless of size or geographic location.

SWESTEP delivers a sustainable alternative for nations, municipalities and companies to build up domestic independent emergency stocks and economically viable production capacity of renewable energy and fuel, regardless of size or geographic location.

SWESTEP’s patented Catalytic Conversion Process (The CC-Process) can convert all hydrocarbon based residues and waste (everything from biomass to plastic) into primarily renewable energy and fuels, but also a sustainable chemical raw oil that can be refined into performance chemicals or green materials/liquids for the entire fossil dependent industry sector (Textile fibers, plastic, cosmetic, medical and more). Additionally, the process produces distilled water and extracts CO2 from the processed material (feedstock).

The CC Process mimics nature’s fossil oil creation (decomposition process), but all made in under six minutes, minimizing emissions and negative environmental impact. A SWESTEP Plant has no chimneys and the production is CO2 neutral and causes no emissions of carcinogenic substances such as furans or dioxins.

Unlike other recycling techniques, SWESTEP can use a variety of input materials as raw material simultaneously during the conversion process.

The flexibility in regard to input material and end-products gives a SWESTEP Plant owner a flexibility to adapt to market needs.