Technically, a new way of operating existing and newly-built fluidized bed boilers by using an oxygen-carrying bed material. Potentially, an innovation that will have significant impact on carbon dioxide emissions connected to combustion of waste and biomass. In summary, a transformation to a more sustainable way of producing heat and power. Meet Lars Bierlein, operating CEO at Improbed, with his heart at the crossroads where innovative technology meets business development.

Hi Lars, describe Improbed’s innovation!

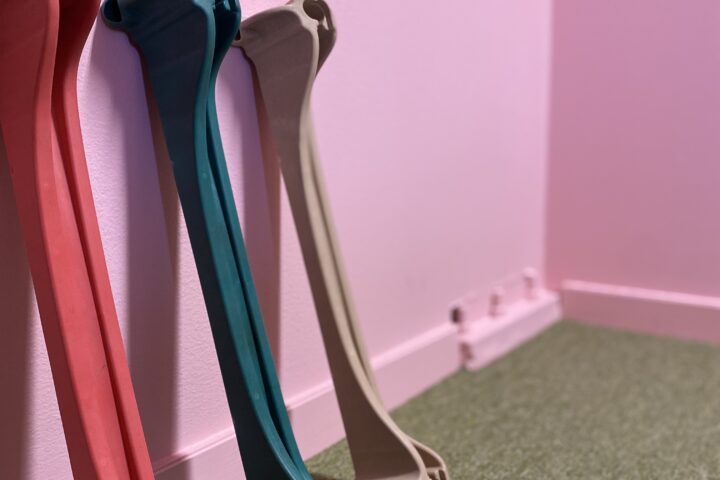

– The short version is that we innovated a new way of operating fluidized-bed boilers. By using an oxygen-carrying mineral as bed material, Improbed™, the oxygen distribution in the boiler is significantly improved. Out of the different existing combustion methods, fluidized-bed combustion is commonly applied in medium to large plants that generate heat and/or power from challenging fuels, often used for district heating. The use of biomass and residue-derived fuel (RDF) comes at a price due to their low and volatile energy content. To reach a higher boiler efficiency, a bed material – commonly quartz sand – is used to buffer heat and create a steady temperature profile in the boiler. Improbed™ is an oxygen-carrying mineral replaces quartz sand and significantly improves the distribution of oxygen in the furnace. This process of transporting oxygen from oxygen-rich to oxygen-depleted zones is crucial and we have found a way to do this super-efficiently. Additionally, the Improbed™-material is easy to separate from other ashes and reuse, which allows us to reduce the material consumption significantly, as much as 90 %.

Improbed™ – the oxygen-carrying mineral used as bed material.

How was the development process initiated?

– The initial research project started in 2013 as a cooperation between E.ON och Chalmers University of Technology, and aimed to investigate the catalytic properties of different minerals for a gasification process. The serendipitous innovation of Improbed™ was triggered when the researchers discovered oxygen-carrying properties of the mineral, which soon was followed by the idea that the material could enhance a combustion process. After initial rounds in lab environments, testing could move on to a 12-megawatt research facility at Chalmers, where fantastic results could be achieved. Thanks to the partnership with E.ON, it was also possible to quickly scale up the testing to an industrial 75-megawatt facility. I was introduced to the project at this point, after working several years with innovation and business development at E.ON. It was time to convert this new technology into business opportunities.

Lars Bierlein, CEO

Who is your target customer?

– Fluidized-bed boiler operators, service providers and manufacturers are our main target groups. We focus on heat and power production based on biomass and waste-to-energy. Until now we have had a strong focus on the Swedish market, and we have initiated projects with several potential and relevant customers. The geographic scope of the Improbed™-concept is truly global, where the Scandinavian origin of the fluidized-bed technology enables a great availability of first-class competence needed for further developing the concept and for supplying high-quality services to our customers.

What other markets would you like to enter?

– Our plan and ambition is to develop global partnerships and serve other markets in Europe, North America and Asia. Fluidized-bed technology has been very successful in China, where there is an extensive need for expanding the waste incineration capacity to reduce the need for environmentally problematic landfills. The forecast of significant market growth and the increased boiler efficiency provided by the Improbed™-concept creates a highly interesting potential.

Why should an investor choose your company?

– The technology is unique and provides tangible customer values. We own several patents and there are scientific journal publications that support the concept. We operate at the crossroads, where new technology meets business development, and the potential of the Improbed™-concept is augmented constantly. We are currently working with two research projects supported by the Swedish Energy Agency. One project, within the Re:Source program, is about the development of Improbed Loop™, the method of separating and re-using bed material supporting the customers’ focus on a circular economy and reduced costs of operation. Further, the Improbed™-concept is very well positioned to support the fluidized-bed industry in capturing the market growth potential of biomass and waste-to-energy boilers.

What is your long-term vision? How will your company develop, looking ten years ahead?

– Market-wise, the goal is for our technology to become state-of-the-art within the fluidized-bed combustion industry. The company will focus on the development of the core technology, continuously providing the customers with additional values from the Improbed™-concept. Improbed will be a driver for evolving both existing and newly-built waste- and biomass-fuelled fluidized-bed boilers towards a circular economy in terms of bed material and ash flows. The multiple performance improvements for fluidized-bed boilers increase the competitiveness of biomass and waste-to-energy solutions, thereby accelerating the replacement of fossil fuel alternatives, as well as reducing methane emissions and other environmental harm caused by landfills. The potential to increase the efficiency of Carbon Capturing is also an important part of the long-term vision, supporting the development of biomass combustion with negative CO2.

Visit Improbed’s profile page at swedishcleantech.com

Visit Improbed’s website

Written by: Hanna Näslund