As the need to transition to renewable energy is increasing, wind power installations are increasing too. In 2021, wind electricity generation increased by 17 % worldwide, and China, the US and Brazil increased the most in wind generation. The increased interest means increased pressure on using fossil materials such as iron and steel, which has a big environmental footprint.

The Swedish company Modvion wants to change the wind power industry by replacing steel and concrete with the renewable material wood. By doing so, the company estimates that up to 90 % of emissions can be saved over the wind turbine’s life cycle. What is more, the wood tower also stores carbon dioxide, which makes the actual climate impact even lower. Wooden construction stores approximately 1.8 tonnes of carbon dioxide per tonne of wood.

How it works

Wood might sound like a building material of yesterday, but it is growing in popularity. The wooden wind turbine towers developed by Modvion are strong and relatively light, up to 30 % lighter than the steel alternatives. High steel towers need reinforcements just to carry their own weight, resulting in more material and higher costs. The Laminate Veneer Lumber (LVL) material in a Modvion tower has higher strength per weight and higher strength per cost than steel alternatives, according to Modvion.

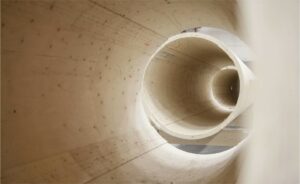

Inside a Modvion wood wind turbine

Modvion’s towers are coated with weather protection coating, making them watertight. This creates a controlled air volume on the inside that interacts with the solid wood volume. The stable system keeps a healthy margin towards any humidity issues.

After the technical life of the turbine is over, the tower is dismounted, and the tower walls can be reused as high-strength beams for the building industry. In that way, carbon can be stored for hundreds of years.

Minimal fire hazard

Wood burns easily if circumstances allow it. However, it is very difficult to cause a solid log to ignite due to its density. In solid wood constructions, the side exposed to an adjacent fire would only start to char at a very predictable and controllable rate. At high temperatures, steel becomes soft, so wood holds its structural integrity for longer than steel.

Easier transportation

Transportation of Modvion’s wooden modules

A common problem with building tall wind turbines is transportation. Modvion’s wind turbine towers are composed of modules that are put together to form a circular section, these sections are then stacked together to create the tower. On-site, a crane can assemble the sections and stack them into segments. Making the wind turbine tower modular makes them easier to transport. The wooden wind turbine towers from Modvion can be transported on trucks on ordinary roads, without the need for lengthy permitting procedures. The easy transport also reduces transportation costs.

Made in Scandinavia

The wood used to build the towers is Scandinavian spruce. All the wood Modvion uses is certified by a reforestation programme, either FSC (Forest Stewardship Council) or PEFC (Programme for the Endorsement of Forest Certification Schemes).

Modvion towers are the most cost-effective option when it comes to building tall towers. In fact, the higher the tower the higher the cost advantage compared to the alternatives available today. Today, Modvion is building its first commercial wind turbine with a tower made of wood. The 2MW wind turbine will be 150m in total height, including the blades, and is under construction this year. The next installation will be for a 6MW wind turbine, among the largest built on land, where the tower alone will be around 150m.